|

|

|

|

|

|

|

|

|

|

Halland Instruments AS

|

|

|

Industries,

applications:

|

|

|

|

|

|

Product categories:

|

|

|

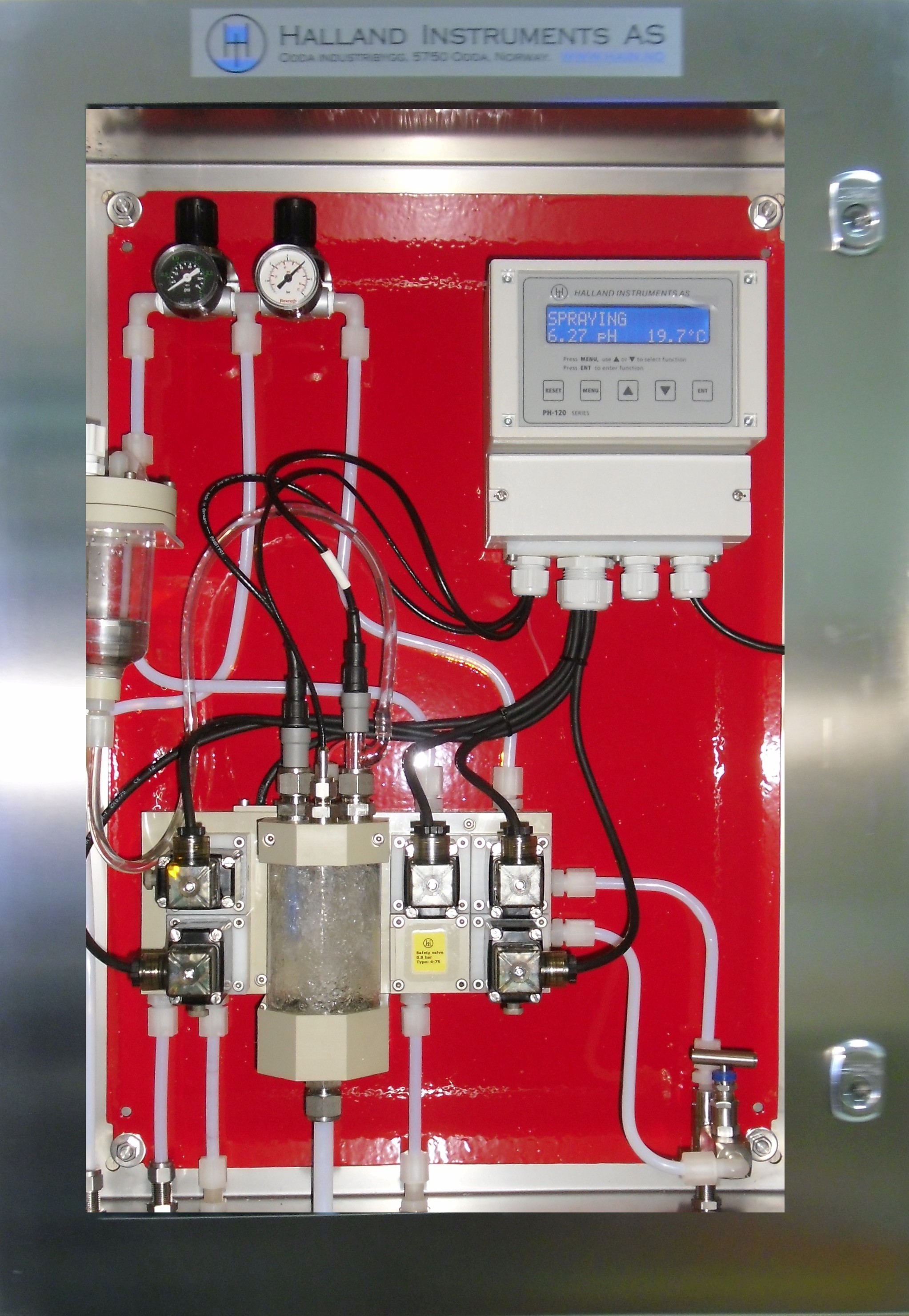

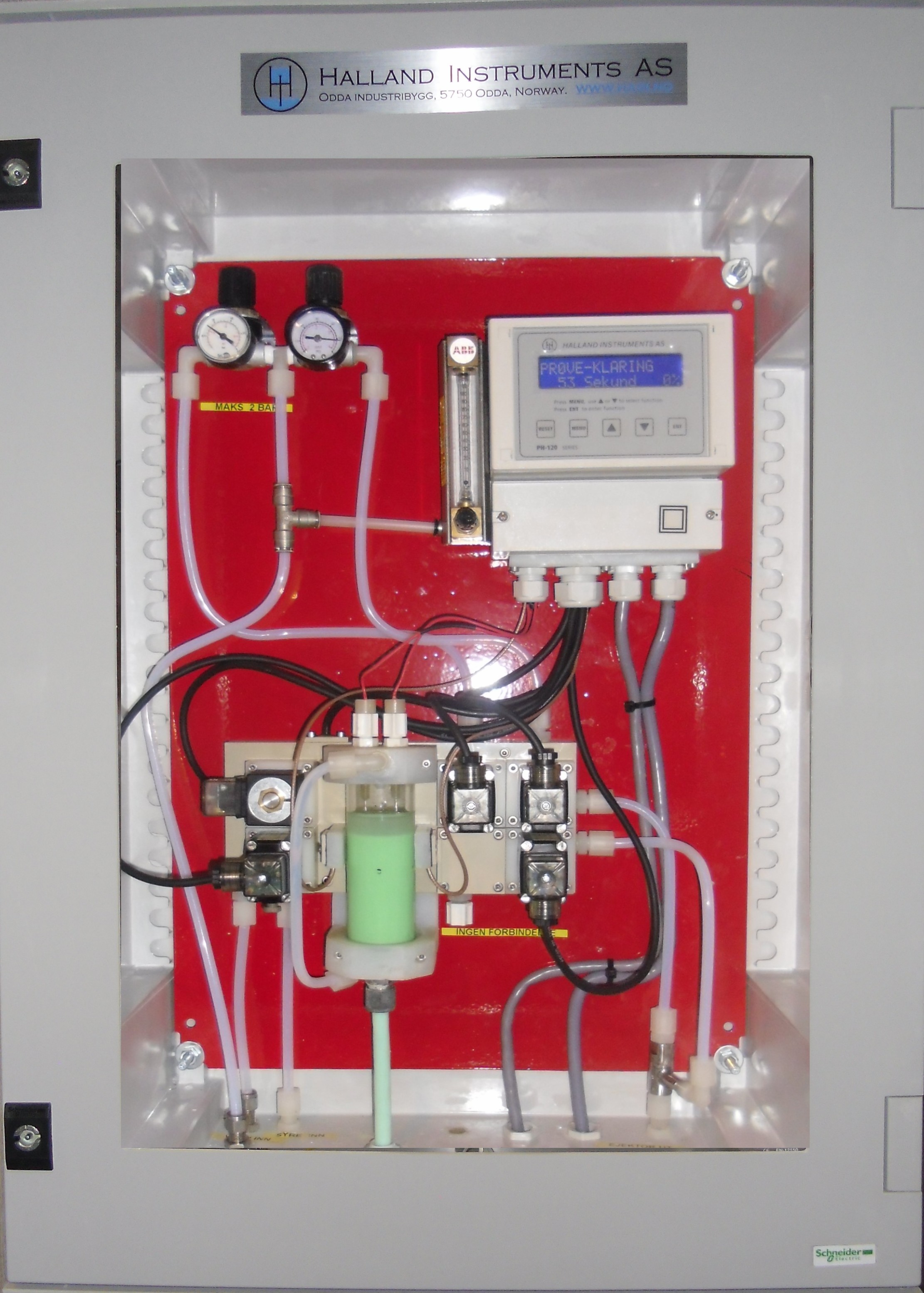

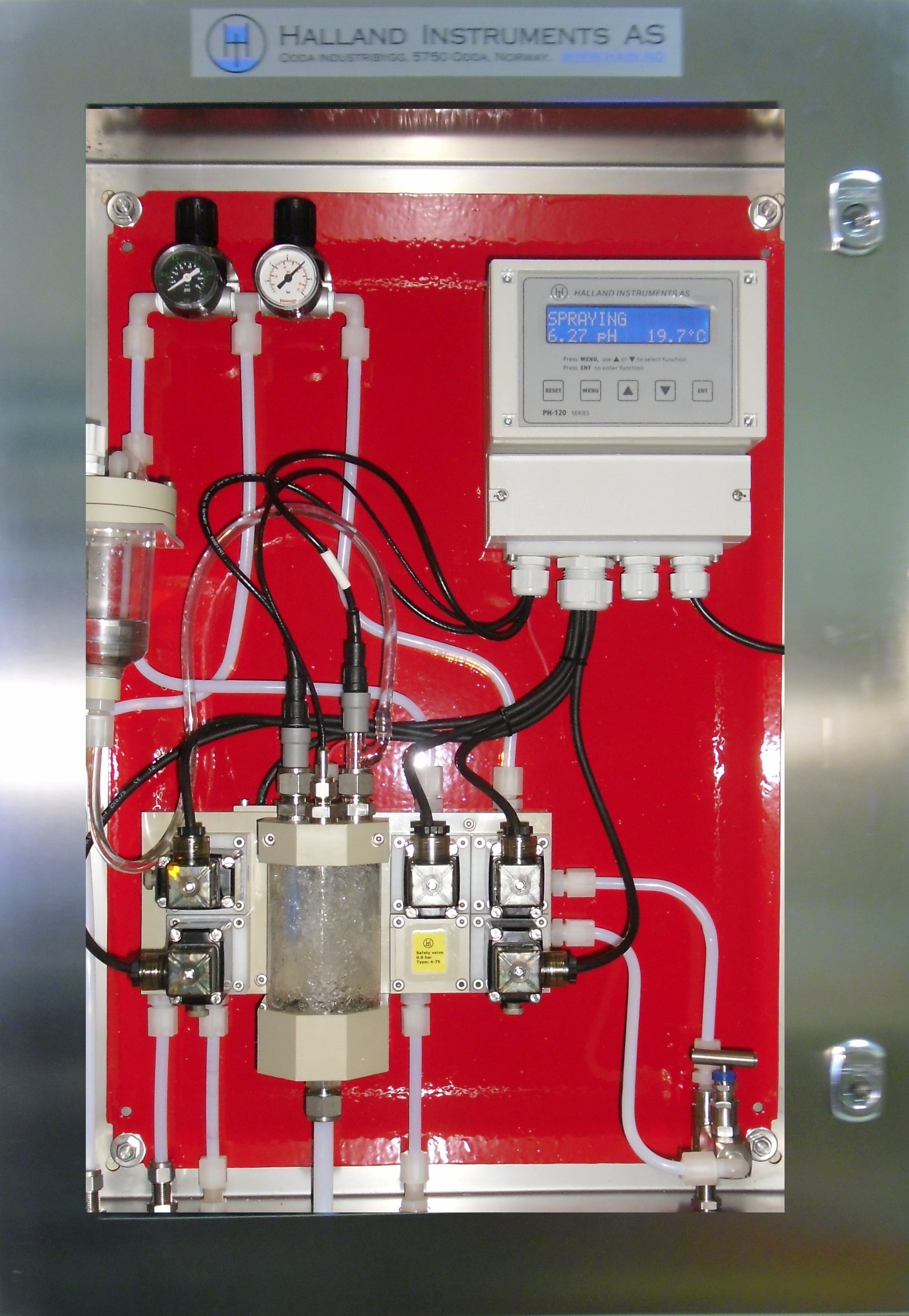

pH analyzers. 4 models: PH-1400 for general use and for processes with sulphuric acid. PH-1500 for extremely corrosive solutions. PH-1600 and PH-1700 for saturated or near saturated solutions.

|

|

|

|

|

|

Automatic sedimentation rate measuring station.

|

|

|

|

|

|

ORP analyzers, two models, ORP-1400 and ORP-1500, ORP-1500 is for extremely corrosive solutions.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pH, ORP and sedimentation rate analyzers for the industry.

|

|

|

|

Our pH analyzers are unique. They are the only pH analyzers that provides measurements with high accuracy, very good long-term accuracy and long lifetime of the electrodes even in extremely difficult solutions for pH measurement such as in zinc production, the nickel matte leaching process, alumina production, the nickel HPAL process, fertilizer production and similar processes.

Inaccurate pH measurements are costing the industries billions of dollars and the industries have a large unnecessary environmental impact. Our analyzers are an important tool for achieving a greener chemical industry: To reduce the consumption of additives, get higher yield, to reduce energy costs and to reduce the frequency of unwanted "mishaps" that causes production loss due to wrong pH measurements.

pH measurements with the electrodes directly in the solution are inaccurate, in-line pH measurements with circulation and systems with retractable electrodes are also inaccurate. The main causes for the inaccuracy are precipitation on the pH electrode surface and pollution of the reference.

Other systems require frequent calibrations, but frequent cleaning and calibration only disguise the problem, the measurements are inaccurate and unreliable. Frequent cleaning, calibration and replacing of the electrode is also expensive and in addition it creates measuring-noise that makes it difficult to run the processes. A short lifetime of the electrodes or the combination electrode is a symptom of low average accuracy and this makes it impossible to optimize the processes.

|

|

|

Earnings and benefits. Our analyzers are instrumental in achieving the following goals:

|

|

|

|

- Reducing the frequency of “mishaps” due to wrong pH measurement, this is quite common, in a zinc plant this can reduce the production capacity with 2-5%. A huge amount of money.

- Increasing the yield and the product quality.

- Reducing the consumption of additives.

- Reducing the energy costs.

|

|

|

|

|

The above points are the big earnings. Below are estimates of the earnings of investing in our analyzers compared with other systems, the average repayment period is 7 months.

If we compare with a pH measurement system with circulation in the nickel chlorine industry or a system with retractable electrode in the zinc industry the earnings for a ten-year period is respectively $ 227,750.00 and $ 202,000.00, and that is just for one measurement.

|

|

|

|

Cost comparison, measurement with the electrode in the process solution, example from a nickel plant:

|

|

|

|

|

Typical electrode costs:

|

Electrode replacement frequency:

|

Yearly costs:

|

|

$ 350 each

|

2 weeks, 26 sensors a year

|

$ 9,100.00

|

|

Calibration frequency:

|

|

Once per shift, 3 times daily, 15 minutes each. 273.75 hours per year, work hour cost $ 60.00

|

$ 16,425.00

|

|

Estimated yearly costs

|

$ 25,525.00

|

|

|

|

|

Cost comparison, measurement using retractable electrode, example from a zinc plant:

|

|

|

|

|

Typical electrode costs:

|

Electrode replacement frequency:

|

Yearly costs:

|

|

$ 500 each

|

4 weeks, 12 sensors a year

|

$ 6,500.00

|

|

Calibration frequency:

|

|

|

Once per day, 30 minutes each. 182.5 hours per year, work hour cost $ 60.00

|

$ 10,950.00

|

|

Replacement of retractable holder, it is a consumable, customer reports same lifetime of Western and Chinese holder; one year

|

$ 5,500.00

|

|

Estimated yearly costs

|

$ 22,950.00

|

|

|

|

|

Cost comparison, our PH-1400 analyzer, example from a zinc plant:

|

|

|

|

|

Typical electrode costs:

|

Electrode replacement frequency:

|

Yearly costs:

|

|

$ 500 each

|

6 months, 2 sensors a year

|

$ 1000.00

|

|

Calibration frequency

|

|

|

Once per week, 10 minutes each, 9 hours per year, work hour cost $ 60.00

|

$ 540.00

|

|

Estimated yearly costs

|

$ 1,540.00

|

|

|

|

|

Equipment and installation costs.

In most industries it is not possible to put the electrode in the process solution. Measurements with the electrode in-line the process require circulation pump, flowmeter, electrode holder, and transmitter.

|

|

|

|

|

Type of installation:

|

Required hardware:

|

Installation cost, work hour cost $ 60.00:

|

Total investment costs per measurement:

|

|

In-line measurement

|

$ 3,850.00

|

40 hours

$ 2,400.00

|

$ 6,250.00

|

|

System with retractable electrodes with automatic cleaning.

|

$ 13,500.00

|

30 hours

$1,800.00

|

$ 15,300.00

|

|

PH-1400 analysers

|

$ 10,900.00

|

20 hours

$1,200.00

|

$ 12,100.00

|

|

|

|

|

Calculated return of investment with a PH-1400 analyzer compared with circulation system:

|

|

|

|

|

Savings, first year

|

$ 23,985.00 ($ 25,525-1,540)

|

|

One PH-1400 analyser including installation

|

$ 12,100.00

|

|

Return on investment

|

6 months

|

|

|

|

|

Calculated return of investment with a PH-1400 analyzer compared with a system with retractable electrodes and automatic cleaning:

|

|

|

|

|

Savings, first year

|

$ 21,410.00 ($ 22,950-1,540)

|

|

One PH-1400 analyser including installation

|

$ 12,100.00

|

|

Return on investment

|

7 months

|

|

|